Bt Research 2015, Vol.6, No.3, 1-10

2

the stationary phase of its growth cycle (Jisha et al.

2013b).

B. thuringiensis

subsp

. kurstaki

(

Btk)

is shown

to produce an extracellular, metal chelator-sensitive

protease during the early stages of sporulation (Li and

Yousten 1975), while Hotha and Banik (1997) showed

that

Bt

strain H14 produced an alkaline protease in an

aqueous two-phase system comprising polyethylene

glycol and potassium phosphate. In fact, because of

overwhelming focus on

Bt-

toxin, exploitation of the

potentials of

Bt

for the production of extracellular protease

with an industrial perspective was found totally

neglected.

Conventionally, commercial production of

Bt

toxin

has been achieved by submerged or liquid fermentation

(SmF), or by batch or fed-batch process (Vu et al.

2010), but advantages of solid-state fermentation (SSF)

for the production of both primary and secondary

metabolites of microbial origin have well been

appreciated by many investigators (Benjamin and

Pandey 1998; Jisha et al. 2013a). Compared to SmF,

SSF received more attention recently, as it uses

simpler fermentation medium, requires smaller space,

easier to aerate, higher productivity, lower waste water

out-put, lower energy requirement, and less

contamination (Benjamin et al. 2013). Combination of

these strategies can yield higher titers of proteases in

the fermentation medium. The product so obtained can

be recovered in highly concentrated form, as against

the dilute form obtained by SmF. However, only very

little is known about the about the enzymes produced

by

Bt

, which demonstrate industrial potentials.

Our group already reported the efficacy of SSF for the

production of

δ

-endotoxin by

Btk

on potato flour (Smitha

et al., 2013a, Smitha et al., 2015a) or soybean flour

(Jisha et al., 2014), and concomitant production of

amylase as a by-product with the enhanced production

of

δ

-endotoxin (Smitha et al., 2013b). Based upon this,

the present study is focused on the purification and

characterization of a detergent stable extracellular

alkaline protease produced by

Btk

upon its growth on

soybean flour supplemented solid medium.

Results

The LB supplemented with 30% (w/v) soybean flour

showed the maximum production of protease at 12 h

incubation; hence, the crude protein (superna tant)

obtained from this modified LB medium was used for

the purification and characterization of protease.

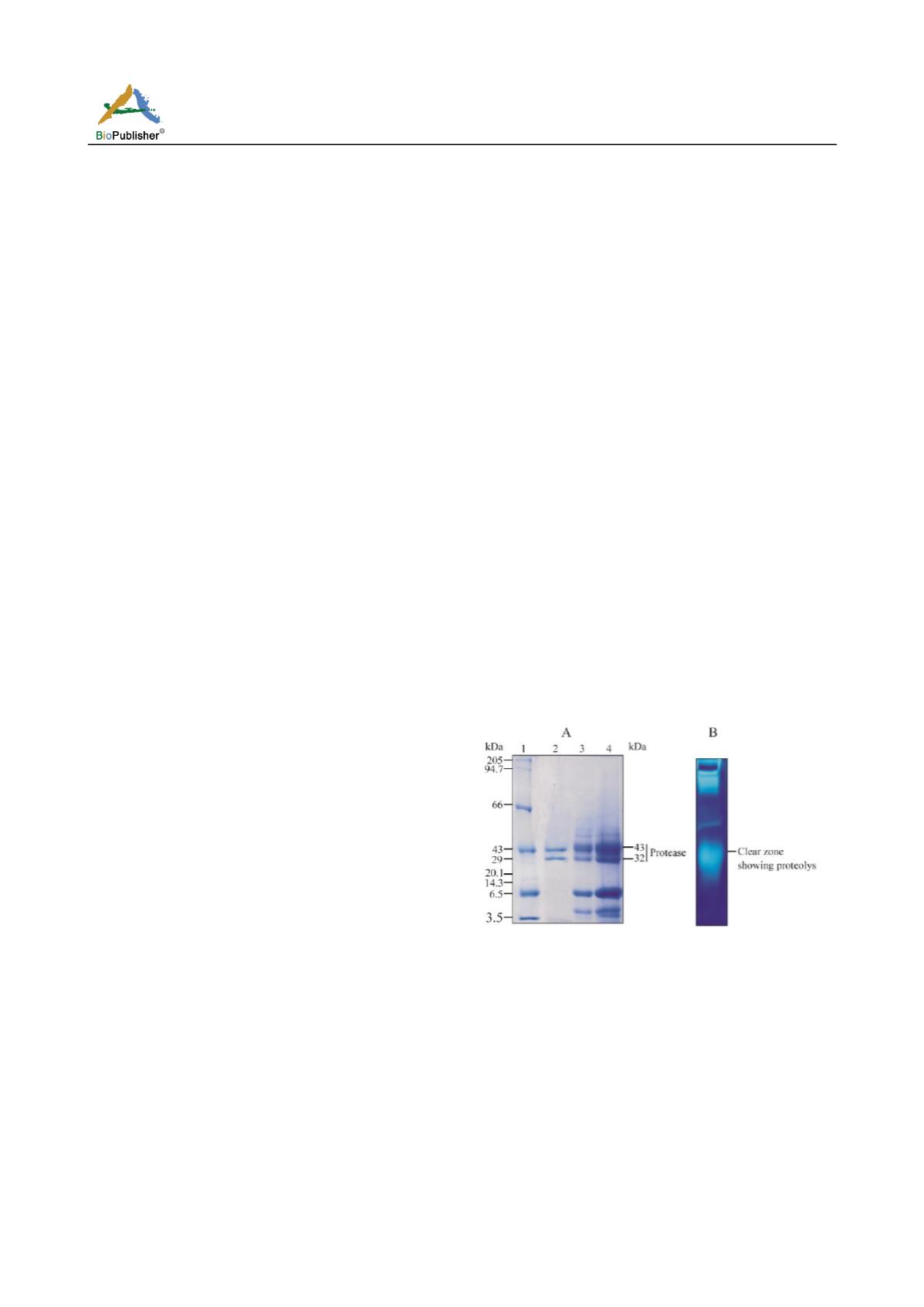

Purification of extracellular protease

The active protease fractions obtained by (NH

₄

)

₂

SO

₄

fractionation (60-80% fraction), Viva spin column

(below 45kDa fraction) partitioning, and Sephadex

G-100 gel filtration unequivocally showed that it

contained two proteases with MW 43 and 32 kDa, as

judged by SDS-PAGE profile (Figure 1); with 12.8

folds purification and 0.3% yield upon Sephadex

G-100 gel filtration (Table 1). The distinct peaks of

the elution profile (fractions between 8 and 17 of

G-100 gel filtration chromatography) also confirmed

the existence of 2 fractions (Figure 2).

Initial activity of protease

Initial assay conditions for protease were: 10 mg/ml

casein (substrate), 7.6 pH (phosphate buffer) at 37

℃

,

and incubated for 20 min. At this condition, the

protease active fraction obtained from sephadex G-100

gel filtration showed 2097 U/ml

eqv

, which was designated

as

initial activity

(for the calculation of fold increase). The

unit of activity was expressed in terms of actual LB

medium (

i.e

., U/ml

eqv

) used for preparing the LB

supplemented with 30% (w/v) soybean flour. The

Figure 1A and B Jisha et al. (Color in web edition only).

1A.

SDS-PAGE profiles showing protease active bands with

approximate MWs of 43 and 32 kDa. (NH

4

)

2

SO

4

fraction

(60-80%) of crude protein harvested from soybean flour

supplemented (30%, w/v) LB at 12 h fermentation was

subjected to spin column MW cut-off (Vivaspin 6 column,

Sweden); subsequently, the lower fraction (lane 3) containing

proteins below 45 kDa was subjected to sephadex G-100 gel

filtration so as to obtain clear protease active fraction (lane 2),

and lane 1 is the profile of standard protein MW marker. Lane 4

is the profile of 40-60% (NH

4

)

2

SO

4

fraction from soybean flour

supplemented (30%, w/v) LB after spin column cut-off. B.

Native PAGE profile of Protease