International Journal of Horticulture, 2017, Vol.7, No. 26, 239-245

242

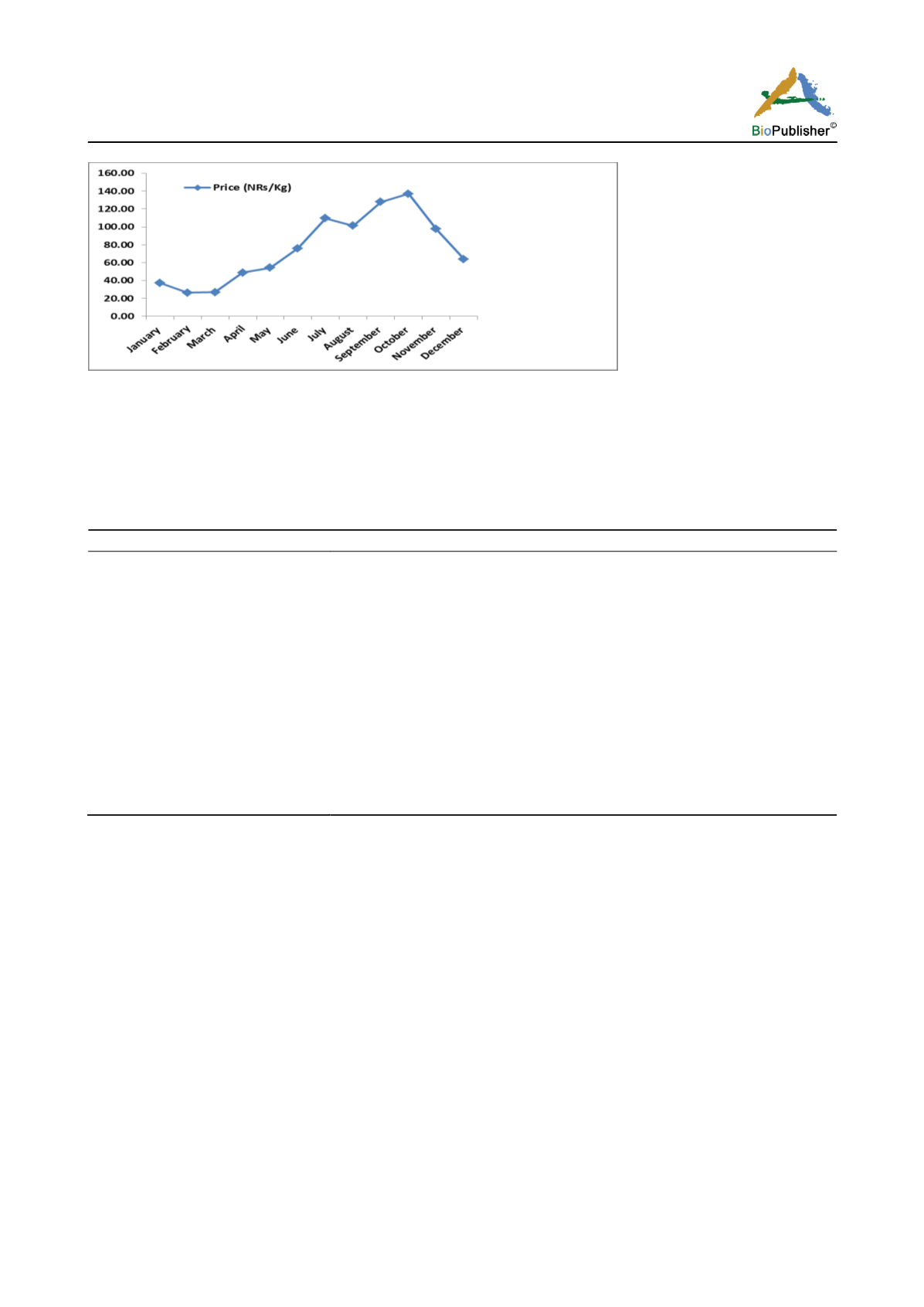

Figure 1 Carrot wholesale price at Kalimati Market in 2016

Note: KFVMDB, 2017

3.4 Supply chain constraints and market-based solutions

It is crucial to assess the market-based solutions to recommend the feasibility and interventions. The assessment

of supply chain constraints and market based solutions intervention and facilitation are suggested (Table 3).

Table 3 Market based solutions addressing supply chain constraints of carrots in Nepal

Constraints

Market Based Solutions

Low volume of production and quality

(size, shape and colour) not meeting the

requirements of buyers

Carrot production zoning

Timely availability of quality inputs (seeds, fertilizer etc.)

Training on carrot production and postharvest handling

Poor market information and pricing

mechanism

Easier access to reliable market information though collaboration between traders

and media agencies and mobile applications for price information.

Lack of processing facilities and

knowledge on postharvest handling

Provision of small scale carrot processing unit near to collection centre

Training on grading, packaging, processing and quality standards to farmers, local

traders, wholesalers and retailers

Poor infrastructure

Establishment and upgradation of collection centres in each production pockets

Provision of cold storage facility

Lack of easy Nepali language

manual/booklet on carrot production and

postharvest handling

Development and distribution of easy Nepali language manual/booklet on carrot

package of practices and postharvest handling

4 Postharvest Losses

It is of prime importance that the carrots should have high quality and should fetches high prices during marketing.

Due to highly perishable nature of carrots, there is always a big challenge to have a good quality at marketing time.

However, the losses can be minimized by proper handling, proper storage and transportation.

In most of the production pockets, grading is not practiced for carrots. Farmers mention that grading is labour

intensive and there is no significant difference in price for graded and non-graded carrots at farmers level.

Traditional packaging practice is found common in the study areas and farmers are slowly adopting the improved

packaging materials too. Normally, carrots packed in Jute bags & plastic crates are used for distant markets.

Carrots are mostly packed in 70-90 kg capacity Jute bags. Traders have started using crates for packaging after

purchasing from farmers. But, growers don’t find it appropriate because of the difficulty in carrying from hillsides

and its high initial investment (NRs 500 per crates). Now some of the farmers are realizing the benefits of less loss

and high-quality produce in crate packaging and they are willing to adopt it. The study showed that postharvest

loss of carrot is 35 per cent. The loss occurred at farm gate is 10%, at collection point is 2%, at wholesale market

5% and finally at retail market 18%. The loss is low at collection point this is because at this level carrots are just

collected and timely goes to wholesale market Kalimati. According to the data collected in May, 2016 the farm

gate price was NRs. 45 and the consumer price NRs. 75 for it (Table 4).