Journal of Tea Science Research. 2015, Vol. 5, No. 6, 1-14

7

such as employee involvement, management support

and continuous focus element, within organization

have a greater impact to quality management

development and implementation (Fredendall et al.,

2006). Thus organizations with objective of

implementing 5S in their workplaces must have a

culture of considering learning as a fundamental

requirement of survival of an organization (Pool,

2000; Nikolic and Nastasic, 2010).

Furthermore, concept of quality circle approach had

a great influence to 5S applications in tea industry;

in which workers banded as small teams working in

specific areas for the betterment and smoothness of

operation where cleaning, organizing and managing

workplace was more efficient with them. According

to Swinton (2004) and Isoeasy (2006), the formation

of quality teams within the organizations had helped

to carryout quality assurance process while contributing

to the continual sustainability of the organization’s

performance over long run. Designing a properly

documented management system was not an easy

task, because it has to consider various aspects

before finalizing a given set of instructions or

preparing a record for evidencing the systematic

approach as well as following the exact system

guidelines. On the other hand, designing was the key

activity in transforming key strategies, requirements

and techniques selected for the system where digital

or paper based systems have to draft all the manuals,

policies, objectives, scope, procedures, prerequisite

programs, work instructions, standard operating

procedures, records, reports and checklists etc.

considering the ISO 22000 FSMS and tea manufac-

turing. It was mandatory to prepare food safety

procedures, prerequisite programs, HACCP plans

and OPRP plans with work instructions for various

operational requirements as well as records for the

evidence which was necessary for auditing purposes;

were systematically evaluated.

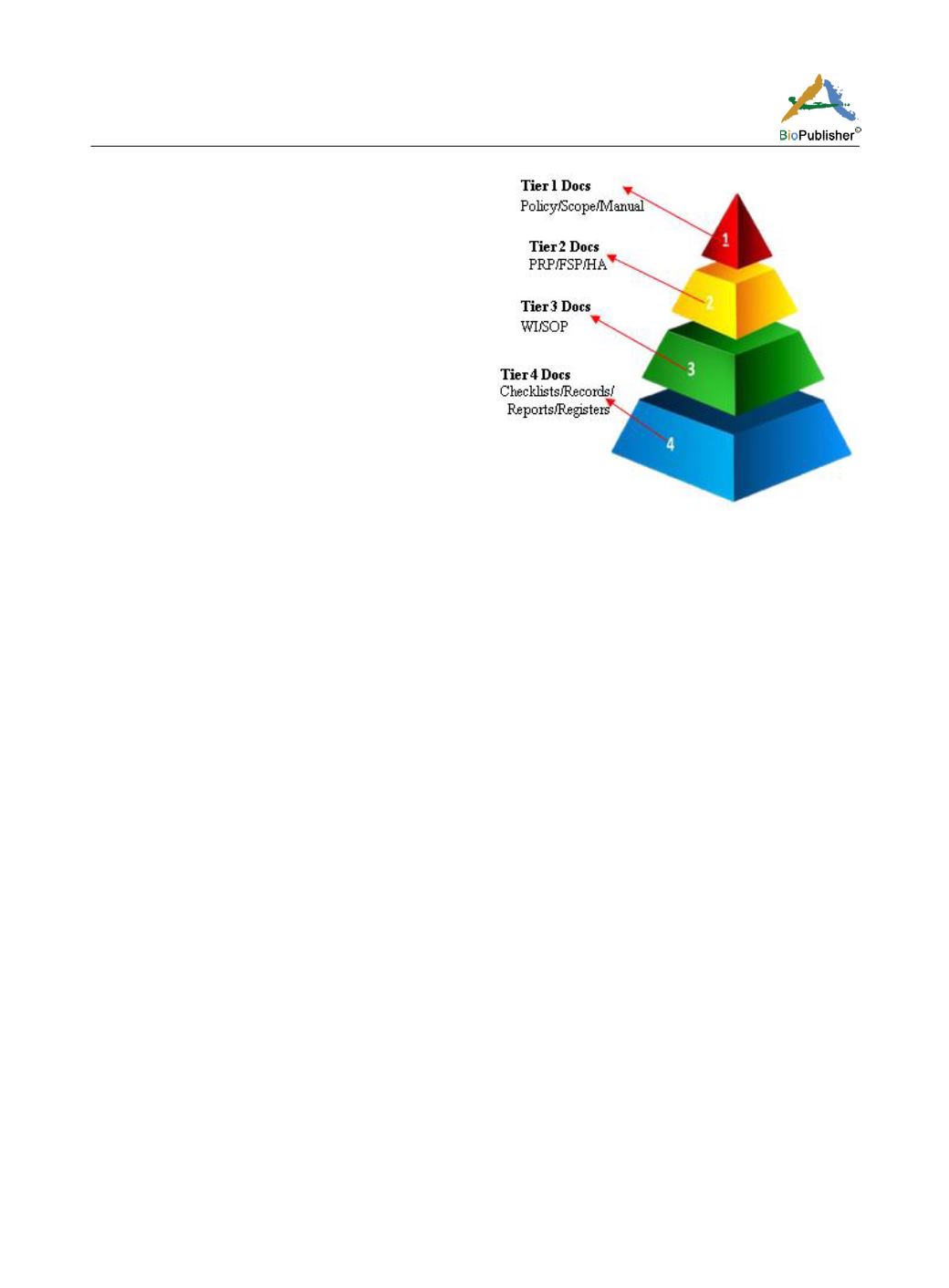

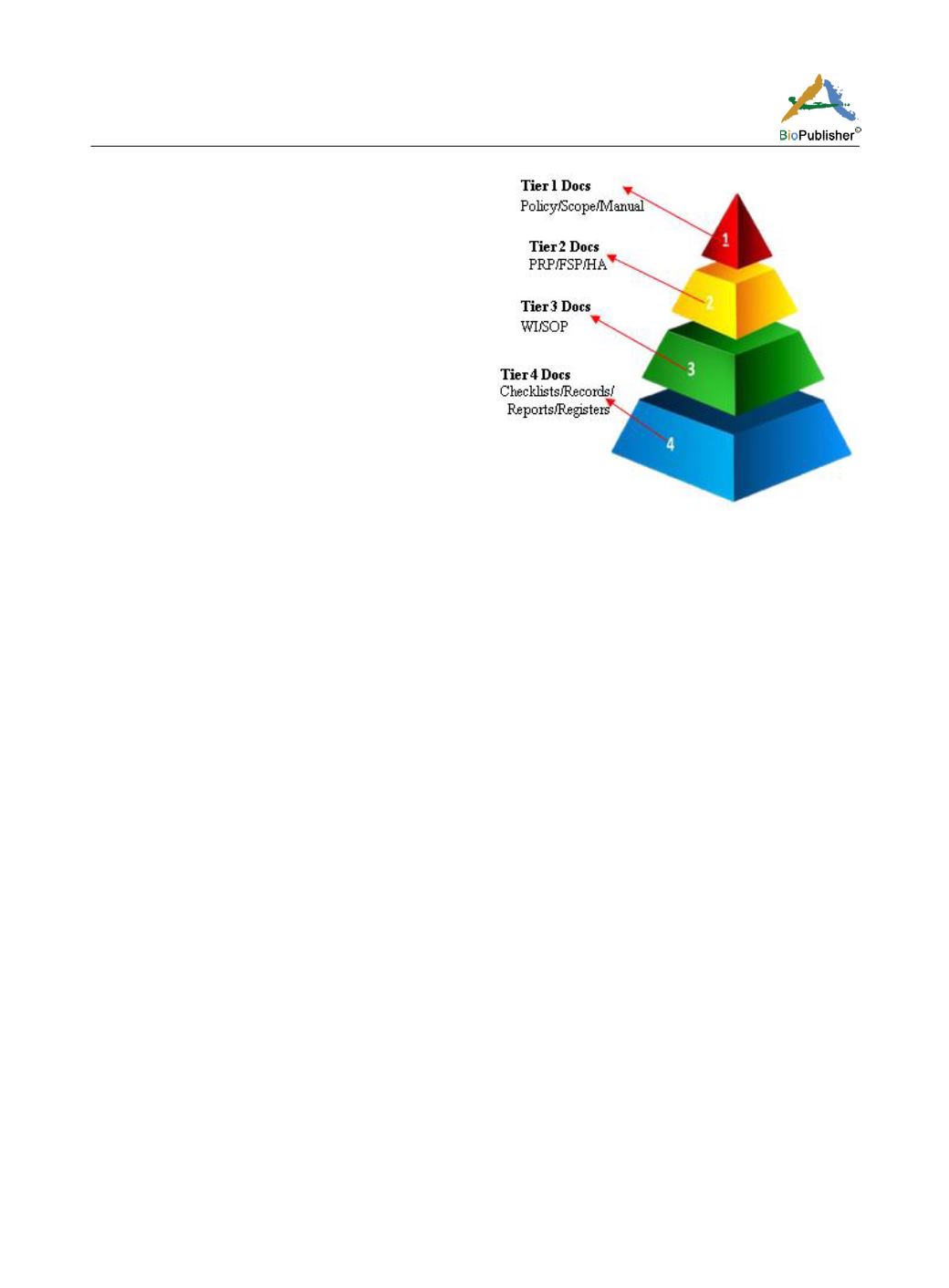

The documentation pyramid was considered as the

cornerstone for the documentation developments,

where the first tire (Figure 02) was consist of ISO

22000 policy statement, scope, objectives and the

manual (manual is optional) . The second tire was

Figure 2 Documentation Pyramid

consisted of food safety procedures and prerequisite

programs where hazard analysis also came under

same layer. However, the 3

rd

layer was basically

used for work instruction where ISO 22000 and 5S

requirements were consolidated in to single set of

instructions while considering to use available 5S

practices with alignment to ISO 22000 requirements.

The 4

th

layer of the documentation pyramid

normally consisted of records, reports, checklists

and any kind of evidencing documents which were

basically keep for the auditing purposes and for the

traceability requirements.

Considering the given requirements, work instructions

were written in following order, where it was

basically to educate operators or labourers in case of

they don’t know what is tea manufacturing or a

specific operation. In such situations, the work

instruction booklets are given to relevant person for

reading in order to raise his/her knowledge on the

specific process and then he may be start the work

under the supervision of the relevant supervisor or

another senior worker. However, the work instruction

has great deal of information on the exact work

where employee will have the opportunity of

understanding standard operating procedure of a

given operation, its cleaning requirements, specific

methods of cleaning and the way it must be visible