Bt Research 2015, Vol.6, No.3, 1-10

5

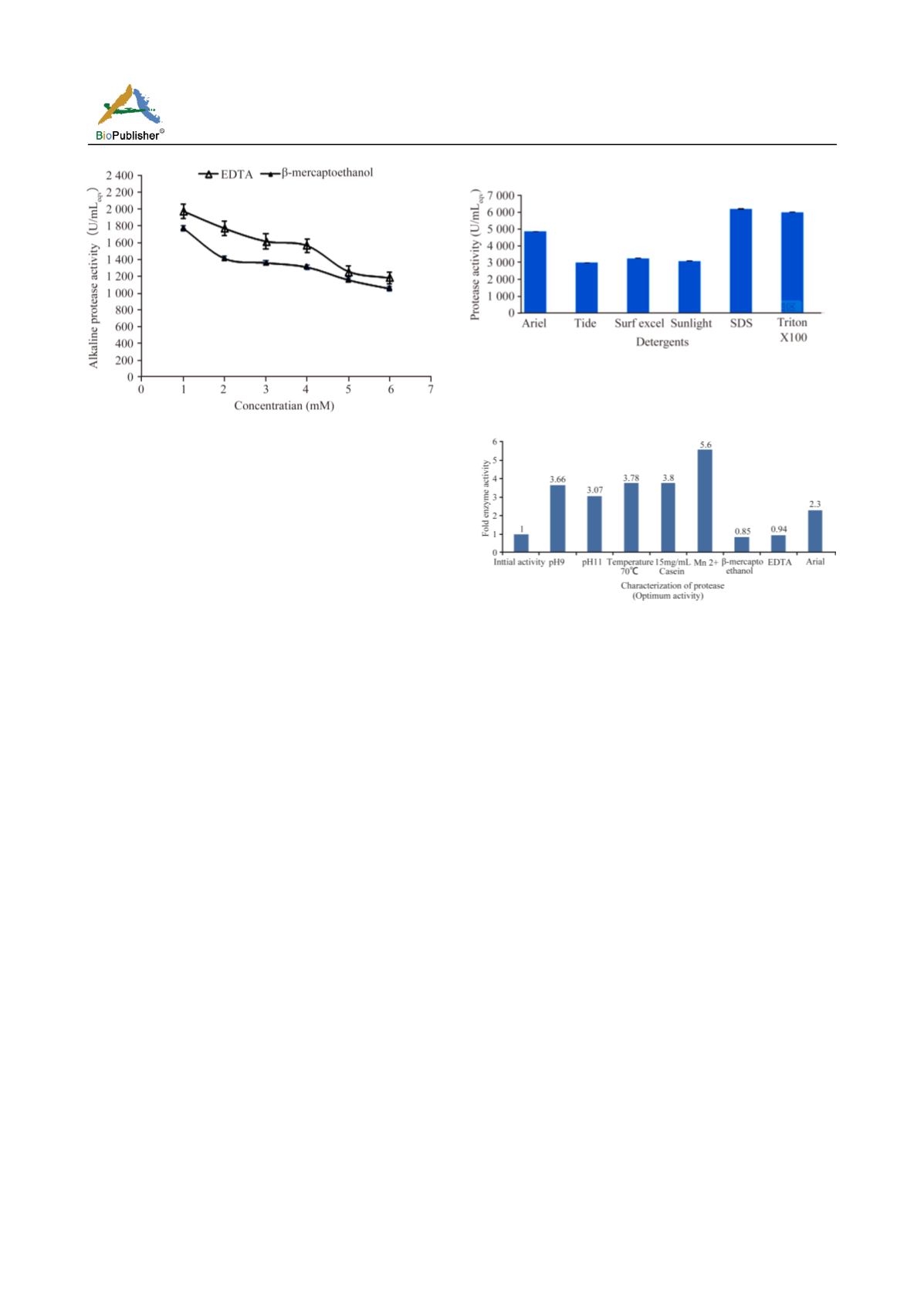

Figure 5A. Jisha et al. (Color in web edition only)

5A. Effect of EDTA and

β

- mercaptoethanol on protease

activity.

U/ml

eqv

) and 15% (1741 U/ml

eqv

), respectively; in

comparison to initial activity (Figure 5A).

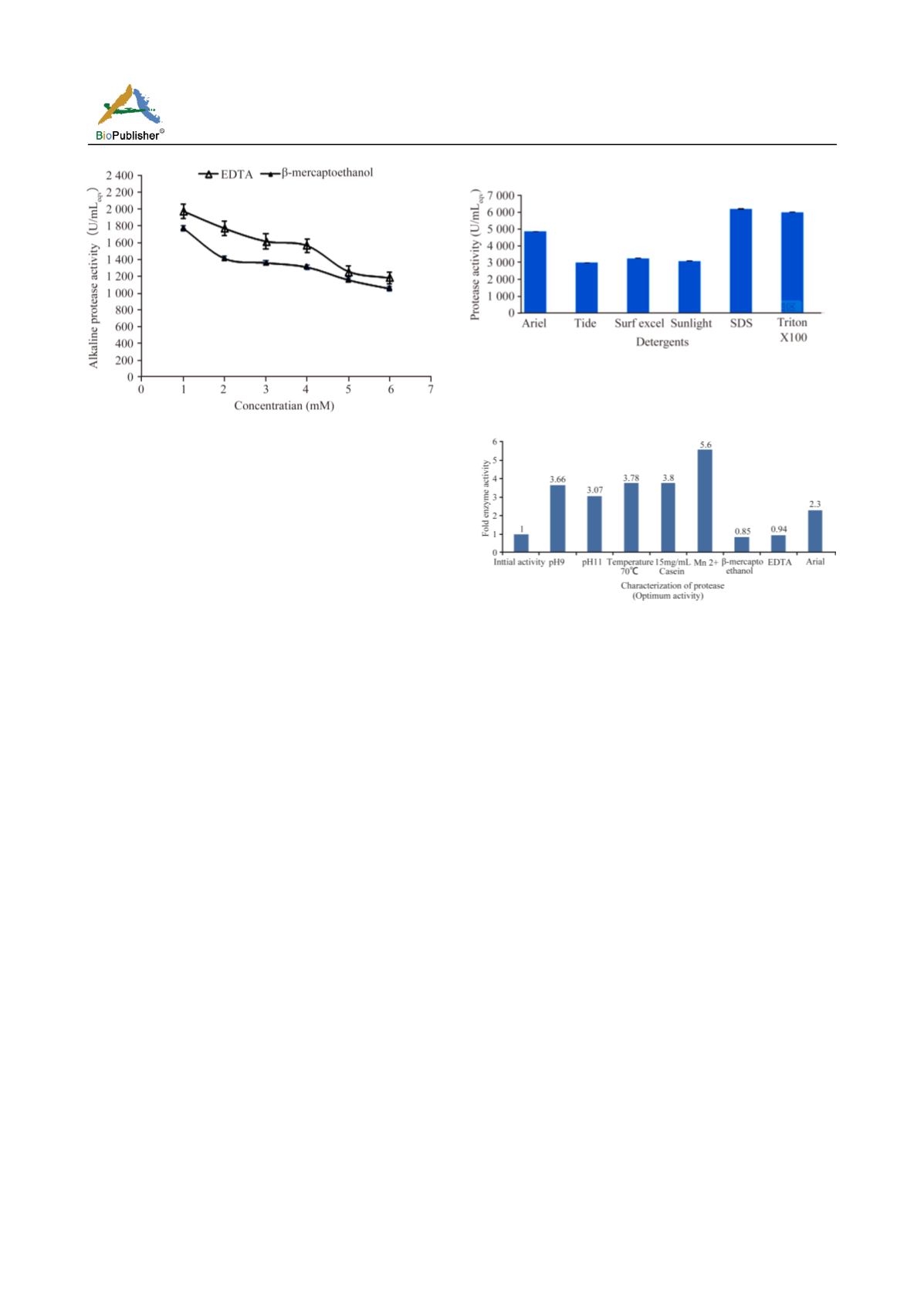

At the optimized reaction conditions, the presence of

detergents in the reaction system variously affected the

protease activity. Protease activity was not disturbed

when incubated with different concentrations (0.1, 0.2,

0.4, 0.8 or 1%) of surfactants like SDS and Triton

X-100. Presence of SDS or Triton X-100 slightly

affected the protease activity;

i.e

., in the presence of

0.2% SDS or Triton X-100, 12% reduction in activity

was noticed, which was in comparison to the activity

at optimized conditions (Figure 5B).

Unlike SDS, and Triton X-100, protease showed good

stability in the presence of commercial detergents

tested (Ariel, Tide, Surf Excel or Sunlight);

i.e

., the

maximum stability showed in the presence of Ariel

with activity 4867 U/ml

eqv

and was over 2.3 folds

increase over the initial activity (Figure 5B); in other

words 40% of the maximum activity obtained at the

optimized conditions. The fold increase is summarized

in Figure 6.

Discussion

Employing biphasic fermentation strategy, our group

already demonstrated the amylase produced by

Btk

as

a by-product during the process of the production of

δ

-endotoxin (Smitha et al. 2013a; Smitha et al. 2013b;

Jisha et al. 2014; Smitha et al. 2015b). Based upon

this biphasic fermentation strategy, a detergent- and

thermo-tolerant protease is demonstrated in the present

study.

Figure 5B. Jisha et al. (Color in web edition only)

5B. Effect of commercial detergents and surfactants on protease

stability on alkaline protease stability.

Figure 6 Jisha et al. (Color in web edition only)

Consolidated data showing the maximum protease activity

under optimized reaction conditions

Characterization of enzyme is an important step

toward developing a better understanding on the

functioning of the enzyme (Yadav et al., 2010). Alkaline

protease in the culture supernatant could be purified

by the conventional procedures involving fractionation by

ammonium sulphate, molecular weight cut-off membrane

filtration, and molecular sieving using sephadex G-100

molecular sieving. Precipitation by ammonium sulphate

is the conventionally used method for the purification

of protein from the crude extract (Bell et al., 1983). In

the present study, the specific activity of the protease

increased from 138 U/mg (crude protease) to 1766

U/mg, after final step of purification (sephadex G-100),

i.e

., 12.79 folds purification and 0.3% overall yield.

These results indicate the effectiveness of purification

method. Various percentage yields and purification

folds were reported for proteases from various species

of

Bacillus:

Bacillus

sp. K25 with 40% yield and

10.08 folds purification (Mathew 1999) ;

Bacillus

sp

.

PS719 with 39% yield and 18.5 folds purification

(Hutadilok-Towatana et al., 1999);

B. subtilis

with

7.5% yield and 21 folds purification (Adinarayana et

al., 2003); and

Bacillus

strain HS08 with 5.1% yield