Basic HTML Version

Plant Gene and Trait, 2013, Vol.4, No.6, 30

-

36

http://pgt.sophiapublisher.com

31

promising feedstock for bioethanol production, large

scale commercial production plants are not in use yet

in the US or EU because of the high production costs

(Sticklen, 2008). Procession lignocellulose into

bioethanol occurs in four main steps: pretreatment,

hydrolysis, fermentation and product separation.

Pretreatment with chemical (acid), biological or

mechanical method is the first step in order to reduce

the size of the lignocellulosic material, hence

increasing the hydrolysis rate of cellulose and

hemicellulose in the second step (Mosier et al., 2005).

Hydrolysis is to degrade the macromolecular cellulose

and hemicellulose into monosaccharides, including

hexose, xylose, mannose, galactose, arabinose and

other oligosaccharides. Monosaccharide will be

fermented into ethanol under the action of the

enzymes. The last step involves a distillation and high

purity ethanol will be achieved (Arshadi and Sellstedt,

2008). At present, among the industry chain from

lignocellulosic biomass into bio-ethanol, a major

limitation is the recalcitrance of lignin, which

decreased the saccharification efficiency. Because the

hydrolysis enzymes are expensive, thereby greatly

increasing the cost of production of bio-ethanol

(Chen et al., 2002).

Lignin, one kind of phenylpropanoid derivatives

deposited on the cell wall of vascular plants, is

composed of polymer compound with high molecule

weight up to hundreds to millions connected by three

lignin monomers by ether bond or a carbon-carbon

bond, which accounts for 15%~35% weights of plants

(Zhong et al., 2000). Lignin can enhance the

mechanical strength of plants, improve cell transport

capacity (Whetten and Sederoff, 1995), and can resist

against pathogenic microorganisms (Duthie and

Crozier, 2000). Lignin biosynthesis of vascular plants

is an important evolutionary adaptation characteristic

to terrestrial environment. Biosynthesis of lignin

monomer is a very complex physiological and

biochemical process in plant, which is the result of

phenylpropanoid pathway conducted by deamination

of phenylalanine (or tyrosine) into cinnamic acid,

through a series of hydroxylation, methylation and

reduction reactions, which ultimately produce three

kinds of main monomer, namely syringyl lignin

(S-lignin), guaiacyl lignin (G-lignin), p-hydroxyphenyl

lignin (H-lignin) (Fan et al., 2005).

Cinnamate-4-hydroxylase (C4H) and cinnamoyl

alcohol dehydrogenase (CAD) are two key enzymes of

lignin biosynthesis (Vanholme et al., 2010; Hamada et

al., 2004). In this experiment, the total RNA was

extracted from Miscanthus with CTAB-LiCl method.

Based on the cDNA sequences of

C4H

and

CAD

isolated

from several monocots reported in Genbank, two pairs

of PCR primers were designed. Cloning and

bioinformatic analysis of cDNA fragments of

C4H

and

CAD

genes were carried out, hence laying a

foundation for the next full-length cloning

of

C4H

and

CAD

genes with RACE (rapid amplifi-

cation of cDNA ends) technique and gene expression

analysis with qPCR (Real-time Quantitative PCR)

technique in the future.

1 Results and analysis

1.1 Extraction of total RNA

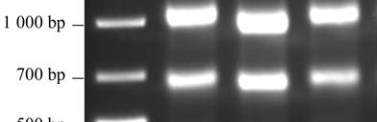

After the total RNA was extracted from

Miscanthus

with

CTAB-LiCl method and then was digested with

DNase I, the purified RNA was detected with the

agarose gel electrophoresis (Figure 1). It indicated that

two bands of 28S and 18S rRNA were clear enough,

and the brightness of the 28S rRNA band to 18S rRNA

is about 1.5 times, which showed that the extracted